How to Produce Heavy Duty Air Filters ?

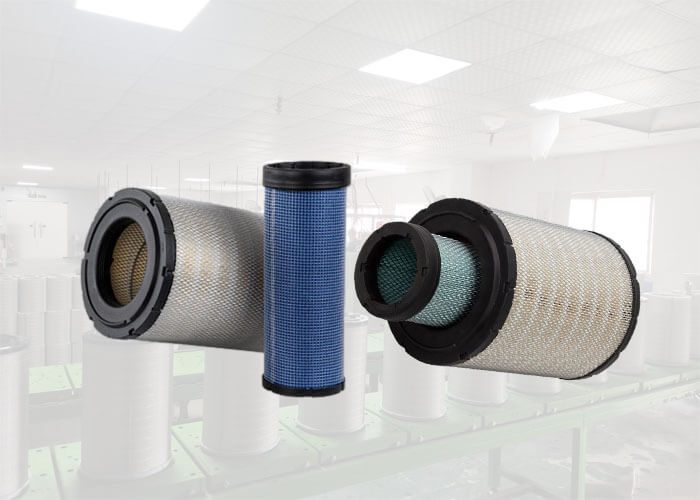

The filtration systerms are where we prepare the key element the filter media.The air filters protect the engines and are used in automotives, trucks, commercial vehicles,heavy duty, industrial and Agriculture. Having been deeply involved in the air filter industry, especially with FILTRAFLUX’s decade-long experience, we’ve honed our manufacturing process to perfection.let’s see the production process of heavy duty air filters.

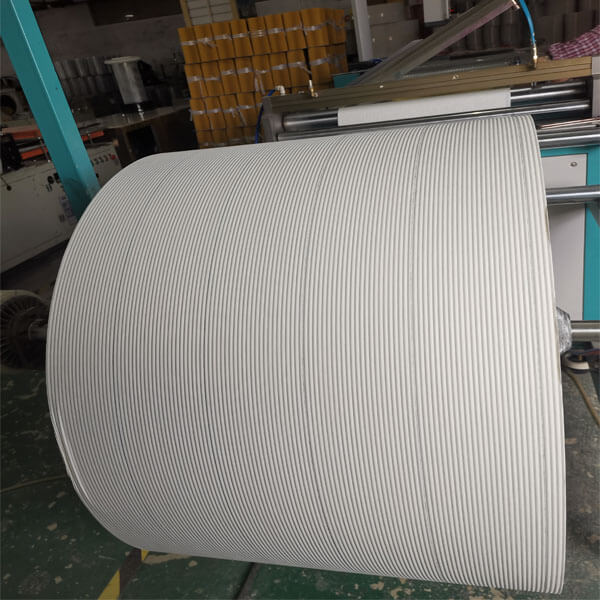

Raw Material-Filter Paper Selection

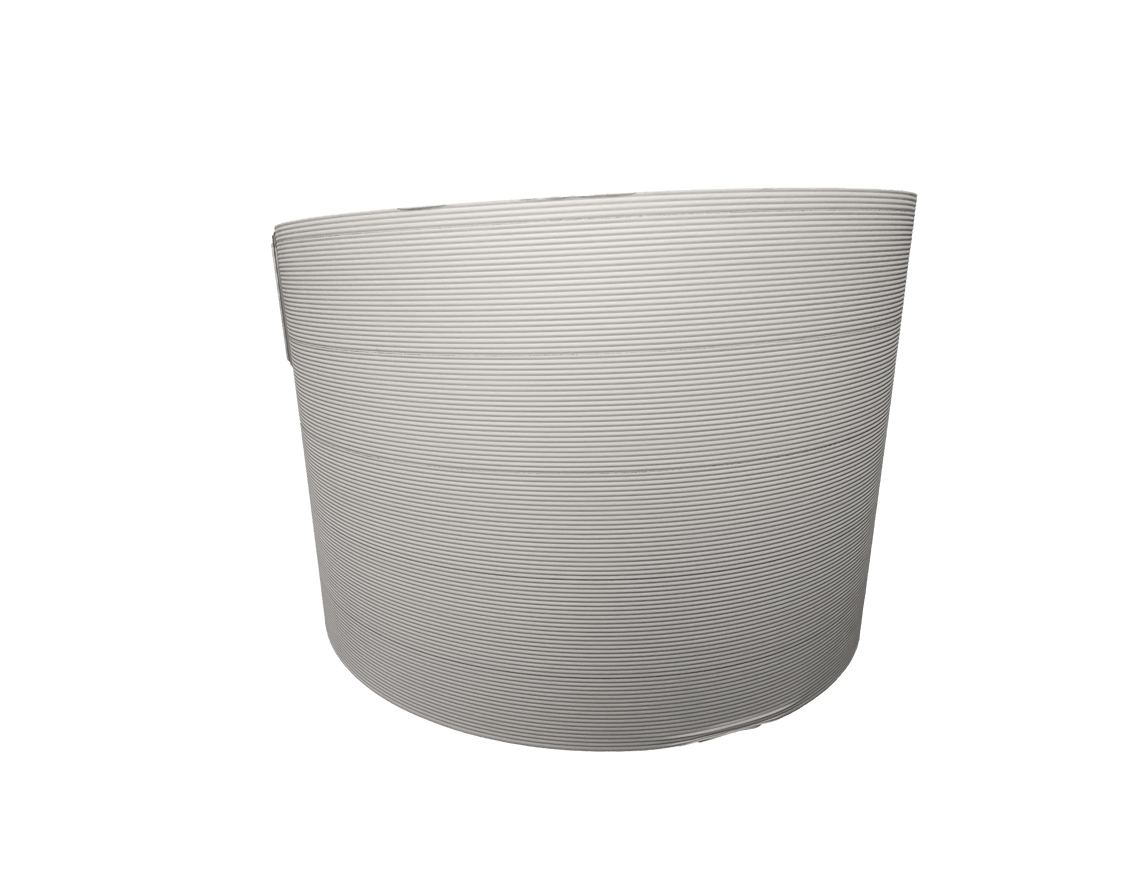

The journey begins with the careful selection of filter paper. This paper is the heart of the filter, responsible for trapping contaminants and ensuring clean airflow. The quality and type of paper chosen directly influence the filter’s efficiency and longevity.

The raw material is generally cellulose paper impregnated with resin which ensures the filter’s non-flammability and resistance to moisture.

Machine Folding of the Filter Paper

Once the right filter paper is chosen, the paper roll will be taken from the warehouse transfered to production line.

It’s fed into specialized machines that fold it precisely. These folds increase the surface area of the filter, allowing it to capture more contaminants without restricting airflow.

At the beginning of the assembly line the raw material is rolled out by preheating the paper obtains the proper plasticity and can be embossed, andtheses embossings will gurantee uniform distribution of the pleats.

Cutting the Filter Paper

After folding, the filter paper is then cut to the desired size and shape. This ensures it fits perfectly within the filter assembly, providing optimal filtration.

Adhering to Form the Filter Core

The cut pieces are then adhered together to form the filter core. This core is the main filtration component, responsible for trapping contaminants as air flows through it.

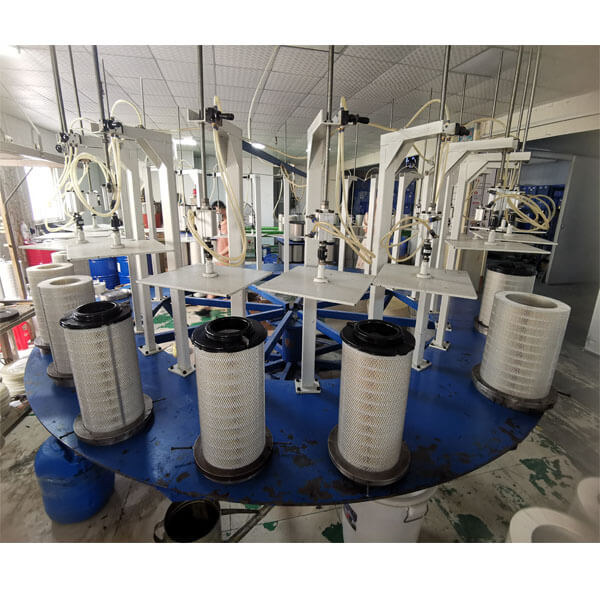

Assembly

Filter Core + Shell + Sealing

Inserting the Inner and Outter Shell

A mesh or wire netting is cut to size, which will later form the inner or outer shell of the filter, providing protection and structural integrity. Inside the filter core, an inner shell is placed. Ourside the filter core, an outter shell is inplaced .This shell provides additional structural support, ensuring the filter core maintains its shape during operation.

Do you know how to make the mesh wire shell? please read our other articles.

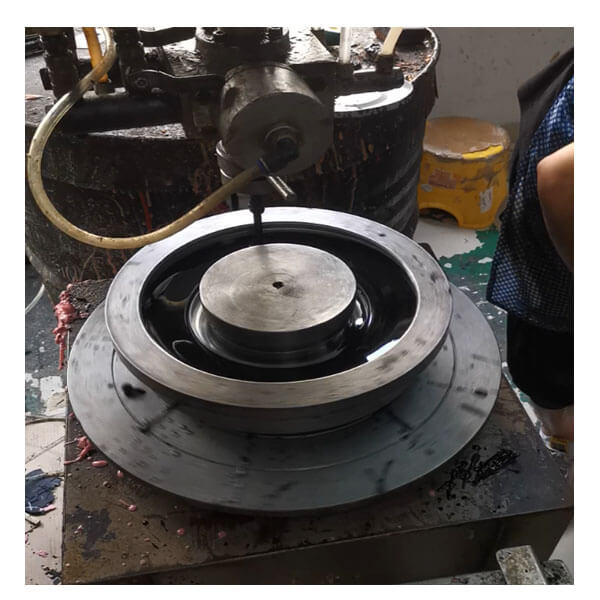

Sealing

we start with the preparation of the aluminium molds firstly. The molds are renforced by the aluminium rings. Use machine out the polyurethane into the aluminium mold, then put the filter into the mold filled with polyurethane. Then wait some miniutes until the liquid polyurethane turns into a finihsed seal. afterwards the insert is turned upside down and placed back into mold this way. it is also connected to the seal on the other side remove the mold, and seal the other side as this way.

Quality Testing

No heavy duty air filter leaves the factory without undergoing rigorous testing. At FILTRAFLUX, we pride ourselves on delivering high-quality products. Filters are tested for efficiency, airflow resistance, and durability. Only those that pass these stringent tests make their way to our clients, like JIM from South Africa, who values quality and reliability.

Packaging And Ready to Ship

The final step involves packaging the filters securely to ensure they reach our clients in perfect condition. Efficient logistics and supply chain management are crucial at this stage.

In Conclusion

The process of creating heavy duty air filters is a blend of science, engineering, and dedication to quality. At FILTRAFLUX, we’ve mastered this process, ensuring that our clients always receive the best products. Whether you’re a distributor, a maintenance service provider, or someone curious about the heavy duty, industry, understanding this process adds value to your knowledge base and ensures you make informed decisions.

Remember, the next time you see an air filter in a heavy-duty truck or construction machinery, a lot has gone into making that essential tool. We ensure the air we breathe and the machines we rely on are always at their best.

Weclome you contact us and talke about the air filters.

2 Responses

Great article! I really appreciate the clear and detailed insights you’ve provided on this topic. It’s always refreshing to read content that breaks things down so well, making it easy for readers to grasp even complex ideas. I also found the practical tips you’ve shared to be very helpful. Looking forward to more informative posts like this! Keep up the good work!

Great article! I really appreciate the clear and detailed insights you’ve provided on this topic. It’s always refreshing to read content that breaks things down so well, making it easy for readers to grasp even complex ideas. I also found the practical tips you’ve shared to be very helpful. Looking forward to more informative posts like this! Keep up the good work!